Zero Liquid Discharge

Ideal for recycling and reusing all wastewater, and becoming a closed-loop system.

A Complete Closed Loop for Wastewater Recycling

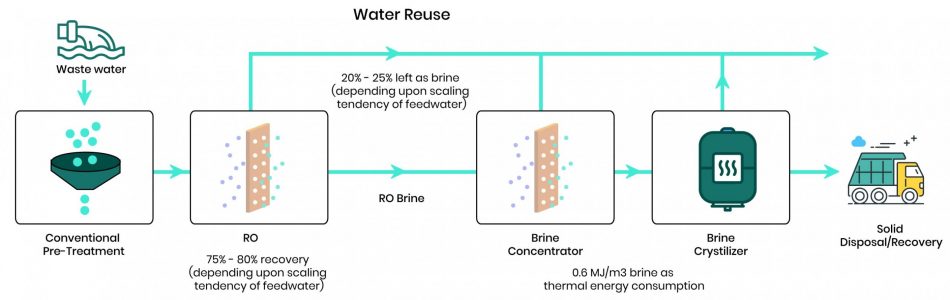

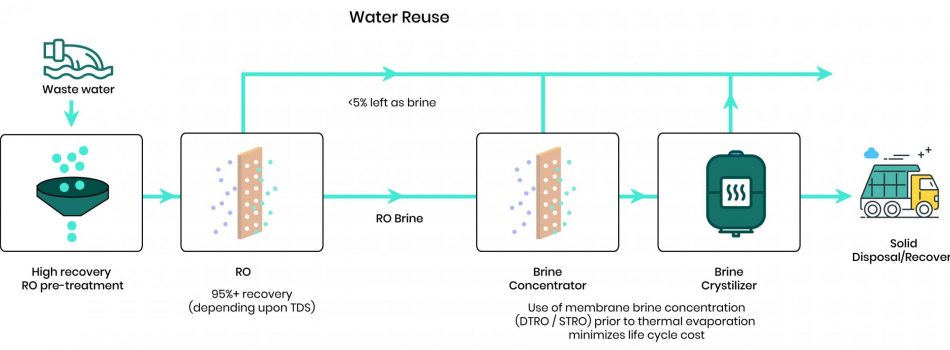

Regulatory requirements and water scarcity are both driving the growth of zero liquid discharge (ZLD) wastewater treatment systems. Circle H2O understands that ZLD projects are both CAPEX and OPEX intensive and that maximizing volume reduction via membranes is essential to minimize the CAPEX and OPEX of the most expensive part of the ZLD process – the evaporator and crystallizer. Our experience with designing reverse osmosis pre-treatment processes to reduce the scaling and fouling tendency of the RO feedwater allows us to push RO recoveries to the osmotic pressure limits of the feedwater, and thus minimize the the high costs associated with the evaporator and crystallizer unit processes.