Membrane Bioreactors

Ideal for when a compact footprint or high-quality treated water are required.

The Many Benefits of MBRs

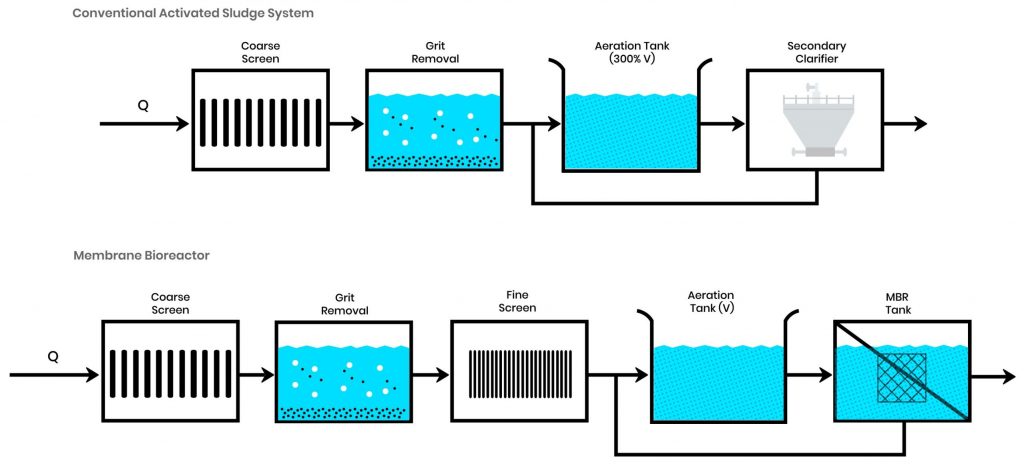

Circle H2O’s deep expertise in membrane bioreactors (MBRs) allows us to design greenfield treatment systems that are far more compact than the conventional aeration – gravity clarifier alternative while producing treated water that is suitable for reuse as cooling tower make-up water, irrigation water, and other non-potable uses. In addition, the treated water meets the silt density index (SDI) specification for reverse osmosis feed water – allowing for use of reclaimed wastewater for a host of other non-potable applications (boiler feed water, clean in place water).

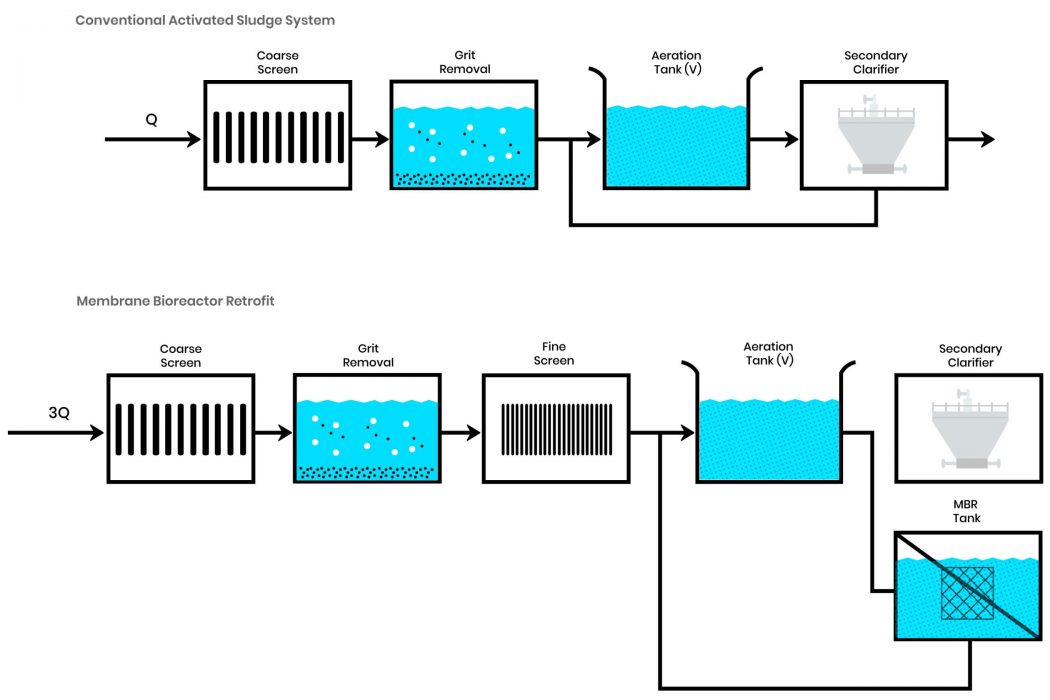

MBRs are also very effective as retrofits to increase the treatment capacity of an existing biological treatment system – due to the ability to maintain a higher inventory of biomass, MBRs can more than double the capacity of an existing biological treatment system without the addition of new structures.

Circle H2O’s experience with various configurations (submerged, external crossflow) and membrane materials (polymeric, ceramic) allows us to propose the best solution for the application.